BLACKLIGHT INNOVATION, INC.

Prior to the SunCell® breakthrough, BrLP developed progenitor power-producing technologies that form Hydrinos through electrochemical and thermal mechanisms. BrLP has formed the whole-owned subsidiary BlackLight Innovation, Inc. to pursue commercialization of these technologies through government contracting, particularly in the case of defense applications of the BlackLight Process such as energetic materials. Dr. Joseph Renick, former Chief Scientist at Applied Research Associates analyzed the characteristics of Brilliant Light Power’s energetic hydrino reaction. Based on the shockwave propagation velocity and the corresponding over pressure, the high-current ignition of water in a silver matrix was measured to produce a shock wave that was 10 times greater than an equivalent weight of TNT.

Explosive Power 20 MW from 10 millionths of a liter volume.

The hydrino products comprises a new field of chemistry that will be pursued commercially. For example, opportunities exist to use the Hydrino® process to produce Di-Hydrino gas that can be used as an economical replacement for helium with numerous commercial and industrial applications, and the unique magnetic properties of Di-Hydrinos can be exploited in novel materials applications.

Novel Hydrino Products.

Further opportunities regard electrochemical reactants and corresponding electrochemical reactions that produce Hydrinos wherein only H2O vapor is consumed to concomitantly directly produce electricity, and thermally regenerative solid fuels developed by the Company undergo a chemical reaction to transform hydrogen to Hydrinos and release a large gain in thermal power that can used directly in heating applications or to produce electricity using conventional steam-based power plant equipment. The solid fuels also have unique applications and potential for energetic materials for the military.

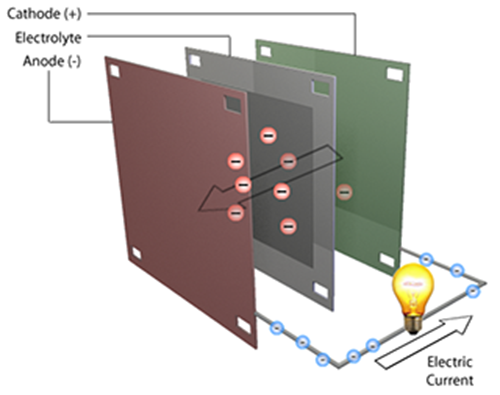

An electrochemical CIHT (Catalyst Induced Hydrino Transition) cell generates electricity from H2O vapor that may be extracted from air using a charge and discharge cycle to convert the H2O into Hydrinos, oxygen, and excess electricity. During a charging phase, hydrogen and oxygen are generated by electrolysis of H2O at the anode and cathode, respectively. Then, the cell is discharged and Hydrinos are formed in an electrochemical reaction that consumes initially the hydrogen and then H2O fed to the cell to produce a large gain in electrical output. The cost is forecast to be under $100 per kW compared to over $5000 per kW for a conventional hydrogen fuel cell. This is in part due to the CIHT cell’s electrical energy released per hydrogen being over 200 times greater, and the CIHT materials being inexpensive. Moreover, fuel cells cannot utilize water as the source of hydrogen, since their product is water. For CIHT, no conventional fuel is required to provide autonomous continuous power for applications such as electronics, power tools, and sensors.

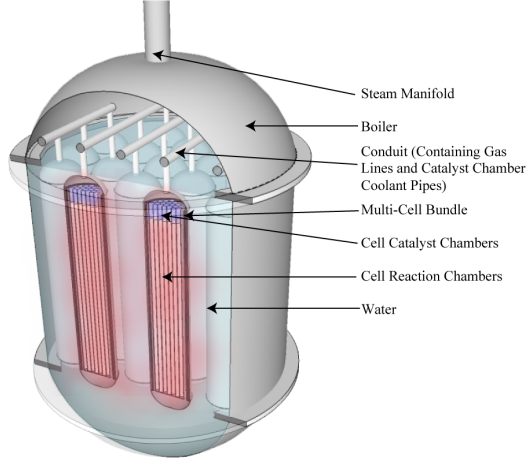

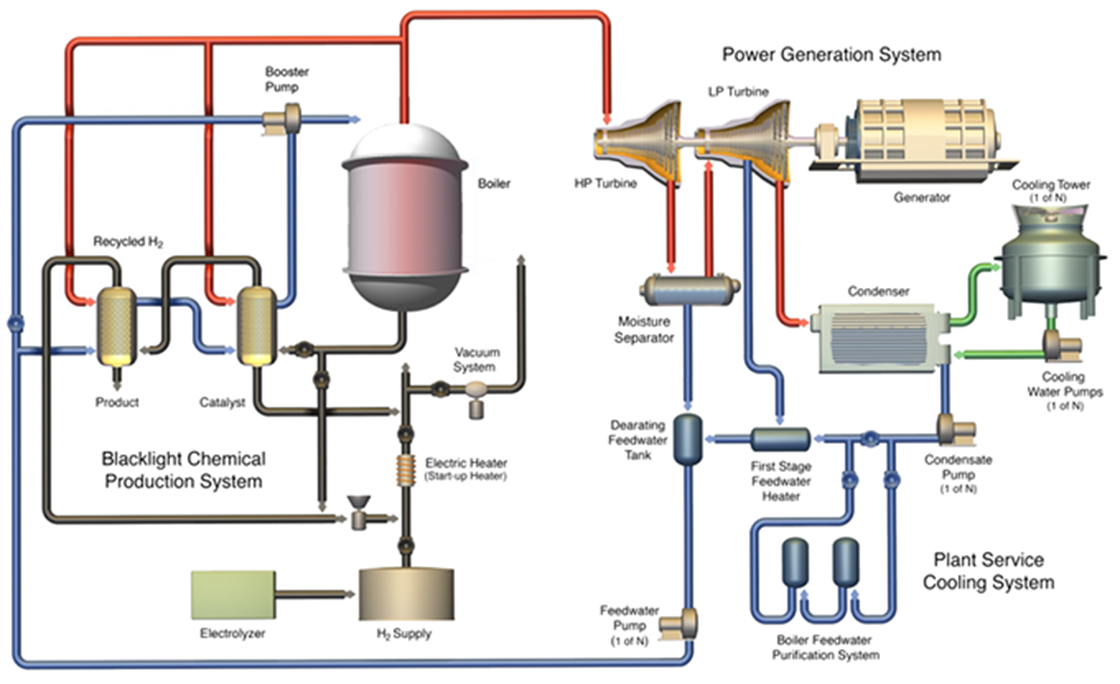

In addition, the Company has developed two power plant system designs that convert the thermal power from thermal producing solid fuel chemistries that in turn can be thermally regenerated into electricity. One comprises a multi-tube thermally interacting bundle of cells wherein the Hydrino reactions are maintained and regenerated alternately in batch-mode in a given cell of the bundle of cells. Heat from the power production phase of a thermally reversible cycle provides the energy for regeneration of the initial reactants from the products. Since there are reactants undergoing both modes at any given time, the thermal power output of the system comprising a bundle of cells is constant. The capital cost is projected to be about $1400 per kW electric. The other system comprises an array of reactor cells wherein power and regeneration chemistries occur synchronously in each cell, and each cell outputs constant power. The capital cost is projected to be about $1050 per kW electric. Thus, the Company believes that continuous generation of power liberated by forming Hydrinos is commercially feasible using simplistic and efficient systems that concurrently maintain regeneration as part of the thermal energy balance. The system is closed except that only hydrogen consumed in forming Hydrinos needs to be replaced.

CATALYST INDUCED HYDRINO TRANSITION (CIHT) ELECTROCHEMICAL CELL

The CIHT electrochemical cell power-producing system converts ubiquitous H2O vapor into electricity as the only source of fuel. As presented in six validation reports, independent leading scientists from academia and industry with PhDs from prestigious universities including the Massachusetts Institute of Technology and the California Institute of Technology have confirmed the CIHT cell. The well-known process of electrolysis extracts the hydrogen atoms (2H) of H2O to serve as fuel to activate the cell. Then, H is converted to Hydrinos with a net release of multiple amounts of electricity than that of the activation wherein additional H2O is directly converted to Hydrinos, oxygen, and electricity.

The CIHT cells are continuously regenerative and operate at essentially instantaneous constant power output during discharge over long duration. In power applications, a portion of a stack could provide electrolysis power for another such that the system is an autonomous source of on-site power, independent of the grid or fuels infrastructure as well as being independent of the sun, wind, or other external variable power sources. The CIHT cell operates under conditions that are similar to those of existing technology such as fuel cells and batteries, but it has extraordinary distinctions that define a new category for CIHT. For example, it does not require an external primary energy source of chemical fuels or electricity derived from chemical fuels, it creates power essentially instantaneously, and uses abundant, nontoxic, commodity chemicals that project a factor of 10 times reduction in capital costs relative to conventional electricity sources. With projected cheaper capital costs than any other electrochemical power source, no infrastructure costs, no fuels cost, and no pollution including greenhouse gases, the CIHT cell, even in its current, non-optimized state, projects commercial competitiveness as stand-alone power in smaller-scale power markets such as portable electronics, power tools, and sensors.

Each CIHT cell comprises a positive electrode, the cathode, a negative electrode, the anode, and an electrolyte that also serves as a source of reactants to form Hydrinos. Due to oxidation-reduction half-cell reactions, a Hydrino-producing reaction mixture is constituted with the migration of electrons through an external circuit and ion mass transport through a separate internal path through the electrolyte to complete an electrical circuit. The cells operate in an electrolytically regenerative manner wherein atomic hydrogen is formed by electrolysis of H2O and supplied to the electrochemical process to initiate the conversion of H2O to electricity wherein the hydrogen catalyst and subsequently Hydrinos are formed by a reaction of the reaction mixture during cell discharge with a net large gain of electrical output.

CIHT cell schematic.

THERMAL POWER SYSTEMS

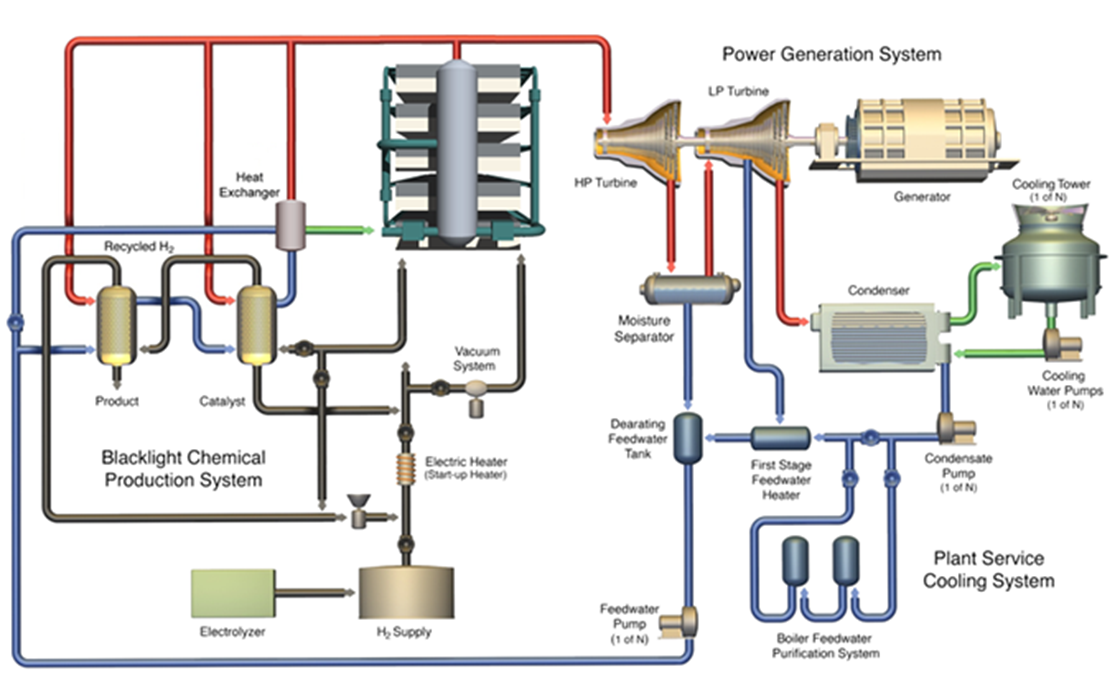

In addition, to electrochemical systems, the Company has developed thermal producing solid fuel chemistries that in turn can be thermally regenerated. Thus, the Company believes that continuous generation of power liberated by forming Hydrinos is commercially feasible using simplistic and efficient systems that concurrently maintain regeneration as part of the thermal energy balance. The system is closed except that only hydrogen consumed in forming Hydrinos needs to be replaced. The solid fuel chemistries have been developed which are very efficient at liberating thermal energy from forming Hydrinos. In principle, green, thermal central and distributed power plants can be operated continuously as power and regeneration reactions of the fuel mixture are maintained in synchrony. Chemistries and engineering designs have been developed for two thermal-Rankine systems. One comprises a multi-tube thermally interacting bundle of cells wherein the Hydrino reactions are maintained and regenerated alternately in batch-mode in a given cell of the bundle of cells. Heat from the power production phase of a thermally reversible cycle provides the energy for regeneration of the initial reactants from the products. Since there are reactants undergoing both modes at any given time, the thermal power output of the system comprising a bundle of cells is constant. The capital cost is projected to be about $1400 per kW electric.

Schematic of a boiler housing thermally coupled multi-cell bundles.

Schematic of a steam driven electrical power generation system having thermally-coupled cells in reactor bundles.

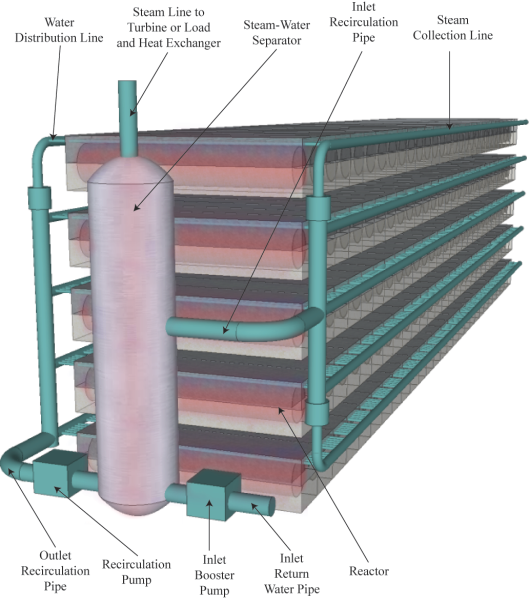

The other system comprises an array of reactor cells wherein power and regeneration chemistries occur synchronously in each cell, and each cell outputs constant power. The capital cost is projected to be about $1050 per kW electric. Based on the observed energy gain and successful thermal regeneration of the solid fuel, the Company believes that environmentally friendly distributed and central power plants can be operated continuously as power and regeneration reactions are maintained in synchrony. The system may be self-contained except that only the hydrogen consumed in forming Hydrinos need be replaced as molecular Hydrino is released. Due to the independence from fuels infrastructure and the absence of any pollution whatsoever, new power-generation business opportunities of distributed generation may exist even at thermal power scales that are achievable in the nearer term using modification of readily available commercial equipment. The system applications for distributed power (1 to 10 MW electric) and central generation retrofit and green-field projects are projected to be very competitive relative to existing power sources and systems.

Schematic of a boiler system having self thermally regenerative cells.

Schematic of a steam driven electrical power generation system having self thermally regenerative cells.

Brilliant Light has published in the engineering literature on power plant designs such as the one comprising a multi-tube thermally interacting bundle of cells wherein cells producing power provide heat to those undergoing regeneration and another comprising an array of reactor cells wherein power and regeneration chemistries occur synchronously. In recent work at Brilliant Light, the application of the catalyst that enables the SunCell® and CIHT cells has given rise to a breakthrough in the development of commercially competitive thermally regenerative solid fuels for utilization in these plants. The high-energy gains observed on solid fuels reactions with instruments that operate like power equipment have been confirmed. Independent off-site tests at several academic and industry laboratories using commercial instruments have confirmed that these new solid fuels release multiples of the maximum theoretical energy possible. Hydrinos were observed to have formed as a result of the heat release.

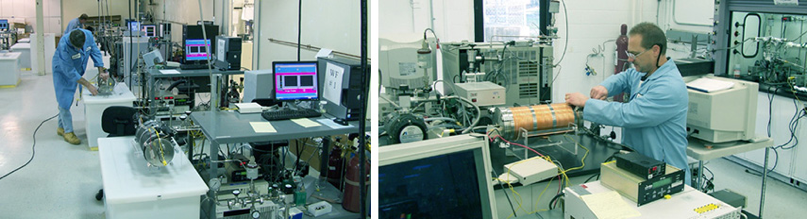

Calorimetric instruments for testing thermal power balance of solid fuels.

THERMAL BUSINESS AND LICENSING

Brilliant Light’s business model for thermal power using solid fuels is focused on developing the technology under government contracting and down-stream licensing power producers to utilize the BlackLight Process as a fuel/heat source replacement. The Company intends to license the BlackLight Process and its related energy technology to power producers and power users globally in all fields of power production and utilization in exchange for royalty fees and milestone payments. Brilliant Light is non-exclusively licensing its process to make power for a fixed royalty payment per kilowatt-hour of thermal or electric (e.g. $x per thermal kilowatt hour or $y per BTU). Brilliant Light anticipates licensees contracting for retrofit of existing plants and for turnkey plants to be built by engineering, procurement and construction (EPC) firms and OEMs. To date, the Company has licensed the rights to produce approximately 8,250 MW of new electrical power to seven companies, including five electrical utilities and two independent power producers. Collectively, these utility companies own, purchase, or manage electric power production of approximately 7,600 MW and service nearly one million customers. The avoided fuel costs from these agreements could be in excess of $2 billion per year.