About

| BlackLight Innovation | BlackLight Process | Classical Theory | Hydrino Dark Matter | Photovoltaic Conversion |

Company Overview

Brilliant Light Power, Inc. (“BrLP” or the “Company”) believes that it has created a game-changing, nonpolluting fundamentally new primary source of energy from the conversion of hydrogen into a prior undiscovered, more stable form of hydrogen called “Hydrino®” that releases two hundred times more energy than burning hydrogen. This enormous chemical energy gain is thermodynamically enabling of using ubiquitous H2O water as the source of hydrogen fuel to form Hydrinos and oxygen. Brilliant Light has solved the theory using classical physical laws, isolated hydrino bound in compounds and as a gas, confirmed Hydrino as the reaction products by many analytical techniques, and identified Hydrino as the pervasive dark matter of the universe.

Click on these images to learn about commercial applications of the classical theory and the data supporting the identification of hydrinos, respectively.

|

|

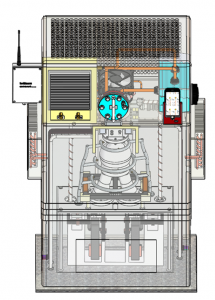

The SunCell® was invented and engineered to harness this clean energy source. SunCell® technology is under rapid development for commercialization. Commercial-design prototypes are continuously producing thousands of watts of plasma, light, and heat. The optical power is ideal for direct conversion to electrical output using commercial concentrator photovoltaic (PV) cells at an estimated efficiency of about 35% to 45% with optimization. The heat can be harnessed for thermal applications using existing heat exchangers, and the plasma can be directly converted into electricity using magnetohydrodynamic converters wherein a commercial design was reinvented to exploit the ideal MHD characteristics of the hydrino plasma over past ion-seeded combustion plasma MHD power plants to have vastly superior performance. Engineering tests to date indicate that the SunCell® is capable of rapid displacement of fuels, power sources, and infrastructure due to its superior performance, lower cost, lack of pollutant by-products, and use of existing mass-produced components. To protect its intellectual property, multiple worldwide patent applications have been filed on BrLP’s proprietary pioneering innovations and inventions. To Management’s knowledge, there are no known Hydrino-technology competitors.

Click on these images to learn more about the SunCell® and concentrator PV conversion, respectively.

|

|

This energy source is based on a new chemical process that releases the latent energy of the hydrogen atom resulting in the formation of the previously undiscovered more stable, Hydrino form of hydrogen. The Company refers to this process as the “BlackLight Process” since enormous intensity ultraviolet (UV) and extreme ultraviolet (EUV) or soft X-ray or black light is emitted. The Company utilizes the BlackLight Process to produce electrical power using its SunCell® that forms brilliant light-emitting plasma that irradiates concentrator-type photovoltaic cells at up to a thousand times Sun intensity to produce the electricity.

Click on this image to learn more about the BlackLight Process.

The only consumable fuel of the SunCell® comprises hydrogen atoms of water molecules wherein gaseous water is injected into the hydrino reaction plasma during operation to serve as a source of HOH catalyst and atomic hydrogen. Optionally, hydrogen gas derived from the electrolysis of water could also be injected. The hydrino reaction is initiated and propagated by a high current flowed through a highly conductive matrix comprising molten silver or molten gallium that is injected by at least one injector that serves a current-supplying electrode that makes contact with its counter electrode through the injected molten metal stream. The injection is achieved with an efficient electromagnetic pump having no moving parts. The current supplied by a capacitor bank and switched on by the molten metal injection may be one hundred times that of household current at a voltage of about one tenth that of a AA battery. H of H2O is converted to Hydrinos with a net release of large multiples of the energy required to ignite the fuel (e.g. 10 times) by application of the high current. The overall reaction is H2O to Hydrinos, oxygen, and power of extraordinary power density with emission resembling the light from the Sun, but at thousands of times the solar intensity at the Earth’s surface. The safe, nonpolluting products can be vented to atmosphere. Hydrino is lighter than air and cannot be contained in the atmosphere such that it is vented to space where it is currently observed in vast abundance (approximately 95% of the mass of the universe is comprised of dark matter or Hydrinos).

To learn more, click on this Hubble Space Telescope image of galaxy cluster Cl 0024+17 shows a ghostly “ring” of dark matter, a prior unknown substance that pervades the universe. Courtesy of NASA/ESA, M.J. Jee and H. Ford (Johns Hopkins University), Nov. 2004.

BrLP is well positioned to deploy commercial products through leasing SunCells® and generating power-sales revenue streams in essentially all power application markets as a replacement of primary fuels and as a primary source of electricity. Manufacturing, supply chain management, installation, and in-field maintenance and repairs will be outsourced. SunCells® producing ten kilowatts to megawatts of electricity are anticipated by adjusting the scale accordingly. Moreover, SunCells® may be ganged to achieve any reasonably sought power such as hundreds of megawatts of electricity available on-site, continuously without interruption.

The capital costs for a low-maintenance system that can have no moving parts are projected to be about 10% that of conventional distributed generation with H2O serving as the fuel and without production of any pollutant. The carbon footprint of the SunCell® is zero while the energy release of H2O fuel, freely available in the humidity in the air, is over one hundred times that of an equivalent amount of high-octane gasoline. It is anticipated to run on demand with load following, continuously for many years. Moreover, SunCell® technology permits independence from existing infrastructure, such as the grid in the case of electricity and fuels in the case of motive power. The safe, nonpolluting SunCell® uses readily available components and cheap, abundant, nontoxic, commodity chemicals, with no apparent long-term supply issues that might preclude commercial, high volume manufacturing. At over a thousand Sun equivalents, the corresponding reduction in the area of the photovoltaic converter gives rise to a projected cost of the SunCell® of about $50 to $100/kW compared to over ten times that for conventional power sources of electricity. Applications and markets for the SunCell® extend across the global power spectrum, including thermal, stationary electrical power, motive, and defense. The Company believes that its technology, comprising the process of the conversion of the hydrogen of water into dark matter and the SunCell® to harness the energy release as electrical output power, represents the solution to climate change while providing power to essentially all applications in the form of electricity at a fraction of the cost of any conventional source, most of which emit pollutants.

Advantages:

Availability of clean power 24/7/365.

- Energy security and independence.

- Autonomous on-site, motive, or motive-to-stationary power that requires no fuel or grid infrastructure.

- The capital costs are projected to be under $100 per kW electric.

- The cost to produce electricity is expected to be well below 1¢ per kWh.

- 17 liters of water would power the average U.S. household for one year.

- One liter of water would power a full-sized car for more than 1000 miles.

- Completely absent any form of pollutant, including carbon dioxide, an EPA regulated greenhouse gas.

- Safety of the power generator and fuel since it is ordinary water.

BrLP believes the process can provide economically green competitive products in a wide range of applications including:

- Residential electrical power

- Commercial electrical power

- Micro-distributed electrical power

- Motive to Stationary

- Motive power

- Marine power

- Aviation power

- Aerospace

- Defense

- Space and process heating

- Commercial/industrial process heating

- Residential heating

- Distributed power

- Central power generation

- Co-generation

- Other applications, including hydrino fuel cells, lighting, lasers and specialty chemicals

Capital and Generation Costs per kWh Comparisons of BrLP Power Sources Versus Other Primary Energy Sources or Power Converters.

Sources: Lazard 9.0, *NREL, BrLP estimates for BrLP

With the discovery of the photovoltaic effect by Becquerel in 1839 and the invention of the first modern solar cell by Chapin, Fuller, and Pearson of Bell Labs, an era of cheap clean energy from the Sun was envisioned for mankind. Realization of that vision is enabled by the invention of the SunCell® that overcomes the impediment of the very low power density of sunlight. With advances since its inception, solar cells have demonstrated the capacity to convert light into electricity at thousands of times higher power levels than sunlight at much higher efficiency at high versus low light intensity. At over 1000 times brighter than sunlight, the corresponding reduction in the area of the photovoltaic converter gives rise to a projected cost of the SunCell® of about $50 to $100/kW compared to over ten times that for conventional power sources of electricity.

The Hydrino molecular product is safe being inert and is also much lighter than air; so, there is a fast rate of its escaping to space after being released into the atmosphere. Therefore, the Hydrino power-generating process does not give rise to pollution, greenhouse gases, or radiation as conventional systems do. Moreover, the source of fuel to form Hydrinos, water, is the fundamental chemical of life and covers most of the Earth. The process of the conversion of water vapor (H2O) to electricity and the products of oxygen and Hydrinos, dark matter form of H2, has unsurpassed fuel cycle sustainability, availability, handling, cost, and environmental advantages.

Applications

The SunCell® is continuously regenerative and can provide essentially instantaneous power output. Thus, shortcomings of alternative power sources such as grid load leveling in stationary fuel cell applications and a battery assist in motive applications are eliminated. In power applications, a portion of the output can power the fuel ignition such that the system is an autonomous source of on-site power, independent of the grid or fuels infrastructure as well being constantly available unlike sun, wind, or other variable power sources.

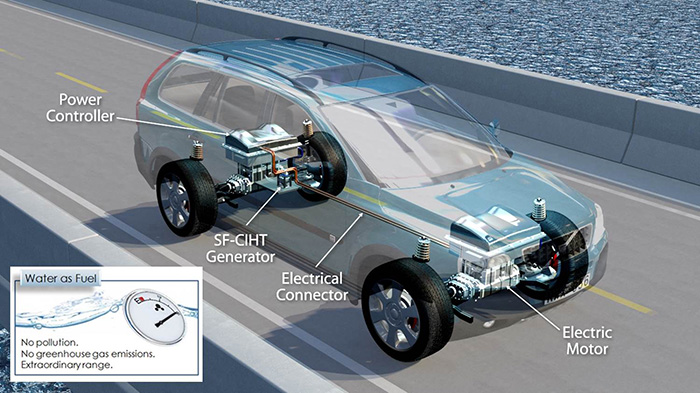

Applications and markets for the SunCell® extend across the global power spectrum, including thermal, stationary electrical power, motive, motive to stationary, and defense. The SunCell® power source is a game changer for all forms of transportation: automobile, freight trucks, rail, marine, aviation, and aerospace in that the power density is much greater than that of any known power system or engine such as internal combustion and jet engines. Consider the automotive SunCell® application. Based on the hydrogen content of H2O and the electricity that can be produced from the corresponding hydrogen, the theoretical range from a liter of water for a standard mid-sized car is over 1000 miles. Based on projections of the SunCell® power density and available materials, a SunCell® that could deliver 300 kW or 400 HP could have a significantly smaller displacement and weight than that of an internal combustion engine (ICE) of the same power. Unlike a gasoline-fired vehicle, the SunCell® is absent fuel costs and pollution of any kind including greenhouse gases. Nor, does the SunCell®-powered car require an expensive, range limiting battery or electric charging as is the case of electric vehicles such as the Chevrolet Volt, Nissan Leaf, or Tesla. Another distinguishing SunCell® attribute over gas and electric powered vehicles is the absence of infrastructure costs. Essentially all power sources should be displaced by SunCell® technology untethered from an electrical distribution or fuel infrastructure.

Concept SUV architecture utilizing a SunCell®.

Business Model

SunCell® power is uniquely and inherently distributed with no need for fuels or grid infrastructure. Management believes that the most cost effective means to electrify the world is also the route of least regulatory impediment. During a short temporary learn-out phase, the Company plans to provide a portion of baseload power to a limited number of selected United States customers. The power will be supplied behind the meter; so, the grid may be available for back-up power. Grid power is prone to catastrophic regional storm failure and terrorism. Since the SunCell® has no moving primary parts and these parts have many years of durability, Management anticipates SunCell® electrical power to be more dependable than grid power. With the establishment of reliability, the Company plans to pursue a totally off-grid global deployment. Management’s financial models demonstrate that providing cell redundancy, and smart controls and load sharing for reliability and peaking power is cheaper and potentially more reliable than a grid connection while avoiding utility regulatory leverage. Ganging a plurality of SunCells® further serves to achieve capacity for the commercial and industrial stationary, heavy marine, rail, and aviation applications. Moreover, since the SunCell® has the unique characteristics of producing no pollution at all and having no fuel cost, low capital costs, and high durability permitting low operating costs, the Company may achieve a further customer-satisfaction advantage and cost savings by switching to a flat daily lease charge with no metering. For stationary power, BrLP plans to sell power under equipment lease agreements and charge a daily rate that on average amounts to about the same flat rate per kilowatt hour as about one half the cost of competing sources of delivered power. A representative United States rate for 50% utilization of the maximum leased capacity is $0.05/kWh total delivered cost. There is a one-time installment fee dependent on the unit’s power capacity that is projected to be about the capital cost of the equipment (e.g. $50 to $100/kW). The maximum capacity may be based on the contracted load and historical norms. As a measure of return on investment (ROI), a unit could pay for itself in less than three months with the electrical power revenue. BrLP plans to maintain ownership of SunCells® while outsourcing the manufacturing, supply chain management, installation, maintenance and repairs, and billing. The SunCell® reduces all historic forms of power to a single fungible commodity enabling a fluid market with power sources being interchangeable and capable of multitasks wherein the traditional market distinctions dissolve.

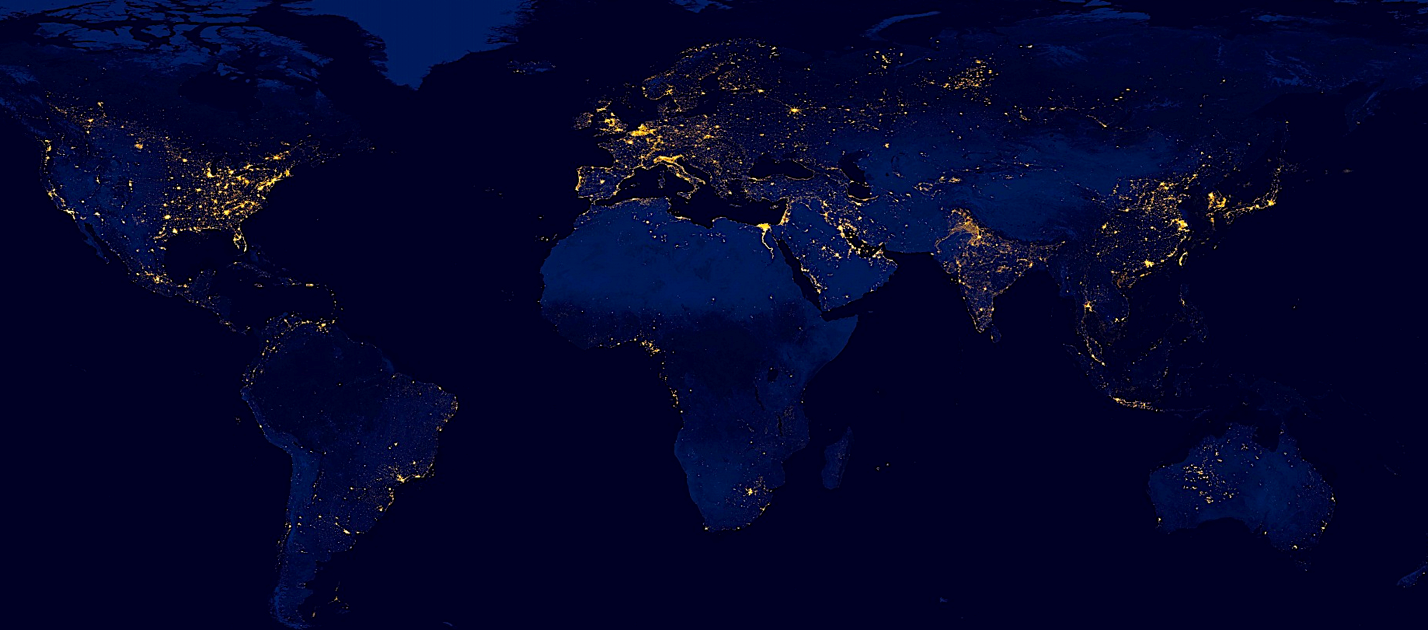

Global established accessible market with expansion opportunities.

- Reinvent electrification as autonomous, completely off grid, mass-produced personal power.

- Flat daily lease charge with no metering.

- Using cell redundancy being off grid is much cheaper than any grid connection and avoids all related utility regulatory leverage.

- Behind the meter during a short temporary learn out phase in the United States, then global push.

As a strategic market consideration, 81% of the population of the United States (US) is urban, and the world as a whole reflects an increasing urbanization trend having with 53% of its population currently residing in cities. Urban centers typically are more developed and require more intensive infrastructure such that 69% of global electrical demand is in urban regions. In any locality, concentrated power is also a feature of the industrial and commercial loads as well as high density residential such as apartment buildings. Industrial and commercial markets are attractive first opportunities representing 51% and 18% of the global markets, respectively. To decrease the number of support centers such as installation, dispatch maintenance and repair, and depot repair centers per capacity and lower sales and other operating costs, the Company plans to focus deployment in the order of large consolidated loads to smaller fragmented loads, and then small, undeveloped loads such as in developing countries.

BrLP plans to lease SunCells® installed in vehicles such as cars, buses, and trucks and charge by the mile or hour of usage to facilitate motive power. Motive power that currently represents 19% of the global power market further enables a further potential massive auxiliary market of SunCell® motive to stationary powering. The Company plans to initially focus on the electric bus and road freight applications wherein a typical bus or large truck can consume as much power and energy as a skyscraper. Experience in these markets will be utilized to enter the automotive and motive to stationary markets. Currently the annual world production of automobiles is about sixty million corresponding to about 20 trillion watts of power generation capacity. As a comparison the US grid capacity is less than one trillion watts or equivalent to less than three weeks of automotive engine (power plant) production. Based on its bill of materials (BOM), the PV converter drives the capital cost of the SunCell®. This component cost is expected to dramatically decrease with volume PV production and higher PV concentration. Management believes that the cost of the SunCell® as the motive engine will be similar to that of the internal combustion engine (ICE), the cost can be amortized over the much longer lifetime than that of an ICE, and the elimination of fuel costs and additional motive to stationary revenue result in the SunCell® having superior economics. Typically, a car engine only lasts about 2000 hours whereas the SunCell® PV is expected by Management to last 20 years with continuous operation based on solar industry PV experience. Moreover, an average ICE vehicle consumes about $30,000 in gasoline over its lifetime. In contrast, a 300 kW SunCell® car engine operating the 8760 hours in a year can generate over $100,000 in electricity sales per year at $0.05/kWh. The total projected cost of the SunCell® generator, control electronics, electric motors, and transmission, is projected by Management to be less than the cost of the of the ICE and drive train of a conventional gasoline-fired vehicle. The corresponding SunCell® economics forecast a shift from the fossil fuel business to vehicle SunCell® leasing with a more competitive mileage or hourly charge without the need to extract, refine, transport, or use gasoline with its unavoidable environmental damage.

The SunCell®’s greater period of capital asset amortization and auxiliary power generation capacity may be better utilized by bifurcating the motive “tool” such as a car, truck, train, boat, ship, or plane from the “power source” being the SunCell®. Such a separation facilitates specialization between the two product fields. Moreover, none of the motive original equipment manufacturers (OEMs) currently have any manufacturing capacity for SunCells®. BrLP plans to control SunCell® manufacturing capacity, supply chains, parts, maintenance and repairs, and installation through outsourcing. This strategy enables at least two possibilities: (i) BrLP buys or leases electric cars or other motive tools from the OEMs at competitive pricing, has BrLP manufacturers install the SunCells®, and BrLP leases the powered vehicle or powered motive tool to consumers with a pass through of the motive OEM’s warranty on the balance of plant, and (ii) motive tool OEMs build the balance of plant, sell it to consumers with a warranty, and BrLP separately leases the SunCells® to consumers. This scenario is very similar to buying or leasing a car and adding the gasoline. It is also similar to the electric vehicle battery-switching business and the natural gas tank swapping business. There are many examples of the tool versus the power source for the tool being separate and made by separate companies: flashlights, consumer electronics, laptops, all devices that plug into an electrical socket, lawn movers, cars, diesel trains, ships, central power plants, anything requiring fuel.

Management is planning for a scenario wherein the motive market such as the automotive market will split; so that the OEMs such as auto manufacturers sell just chassis, and BrLP separately leases the SunCell® power source and bills for usage. BrLP will then acquire direct billing, and maintenance and repair access to the consumers. As in the stationary case, BrLP plans to sell power under lease based on used capacity. This structure would also permit BrLP to directly control secondary applications of the SunCell® such as motive (car, truck, rail, marine, aviation) to stationary or motive to motive such as a car powering a car carrier such as a truck, ferry, or cargo ship. New applications of the inexpensive, clean massive motive to stationary power are anticipated such as water treatment, desalination, continuous hydroponic farming, fish farming, production of commodities and materials such as hydrogen, aluminum, steel, paper, and glass, land reclamation, super power intensive mass transit such as the Hyperloop and high speed rail (maglev) and defense applications such as energy-directed missile defense (e.g. free electron and other lasers and railguns).

BrLP is seeking major power consumers for several early adopter lease agreements for delivery of purely green power from its new primary power technology wherein BrLP delivers and maintains equipment for a very competitive equivalent kWhe rate. BrLP is also seeking contracts regarding the engineering and manufacture of the SunCell® comprising the light source and the photovoltaic converter. Specialized engineering companies and manufacturers will perform the engineering to optimize the SunCell® as a commercial product that has the capacity to have no primary moving parts and be very durable. These companies would then manufacture, supply chain manage, install, and perform in field maintenance and repairs. BrLP is further seeking agreements with electrical contractors that have the required capacity to provide installation, maintenance, and repair services of the magnitude needed to meet national demand.

Prior to the SunCell® breakthrough, BrLP developed progenitor power-producing technologies that form Hydrinos through electrochemical and thermal mechanisms. BrLP has formed the whole-owned subsidiary BlackLight Innovation, Inc. to pursue commercialization of the corresponding spin-off technologies such as energetic materials.

Click on this image to learn more about BlackLight Innovation, Inc.

Facilities and Employees

Brilliant Light owns and occupies a 15,000 square foot modern research and development facility equipped with state-of-the-art laboratory equipment. The Company’s technical core competencies are (i) SunCell® engineering, (ii) system engineering and development, (iii) photovoltaic power conversion, (iv) characterization of SunCell® chemical processes, (v) thermal power measurement, (vi) chemical, material, plasma characterization and spectroscopy, (vii) theoretical physics, and (viii) molecular modeling. Currently, the Company has twenty-two employees and eight consultants wherein the majority of employees and consultants are scientists and engineers. With commercialization of the technology, Brilliant Light plans to establish licensing offices throughout the US as well as establish foreign offices to provide a regional presence as the licensing activity expands.

![[BrLP]-Transparent-Logo-White-240px](https://brilliantlightpower.com/wp-content/uploads/2023/08/BrLP-Transparent-Logo-White-240px.png)